SACMI launches 4 new

GME 30.40 one-piece cap models, extending its range in the

26/22 mm family to offer the broadest array of solutions for the new

GME neck finishes. In parallel, SACMI provides a complete

product development service, helping customers make the transition with profitable, certified, ready-to-use solutions.

GME 30.40 neck finish for CSD, still water and N2 pressurized water.

Intended for both carbonated soft drinks (CSD) and still water/nitrogen-pressurized water, the new GME 30.40 neck finish caps deliver unmatched results in terms of sustainability, quality and performance; they also provide plastic savings of up to 30-35% while meeting the same requisites.

Tethered-friendly.

SACMI’s AB26 CSDT5 is a 1.8 g CSD tethered-compatible cap that complies with the strictest specifications established by the main international brand owners. The new GME 30.40 neck finish cap belongs to a broad family of tethered solutions developed by SACMI to meet every market need ahead of regulatory changes within the industry.

Ultralight caps (also for CSD).

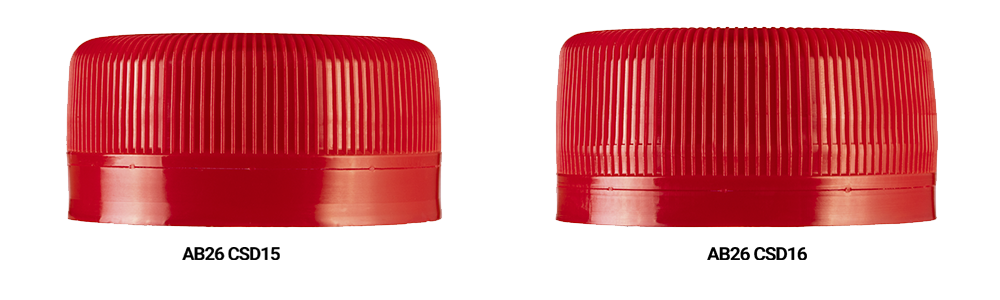

SACMI AB26 CSD15 is the lightest solution on the market to be developed for the GME 30.40 neck finish: in just

1.65 grams it delivers all the strength and sealing performance needed on CSD caps.

The best consumer experience.

Consumption habits vary widely across countries and regions and play a key role in speeding up the transition in ways that are profitable and productive for our customers.

SACMI aims to deliver the same consumption experience provided by today’s most widespread standards, hence its development of the

AB26 CSD16: a GME 30.40 cap weighing just 1.80 g that ensures ultra-easy opening (i.e. outstanding

grip) thanks to the extensive knurled surface (the same as on traditional PCO 1881 caps).

Still water, new tetherable ultra-light caps.

The world’s main markets are already transitioning to tethered standards: SACMI responds with the AB26 WT8, a new GME 30.40 neck finish cap weighing just 1.25 g for still water, which joins the other ultra-light SACMI solutions already on the market (1 g and 0.8 grams for water). Like the analogous cap for CSDs, this solution belongs to the broad family of tethered caps designed by SACMI to take the industry forward.

Innovative technology, machines and unmatched expertise.

The industry’s leading compression technology provider (CCM, Continuous Compression Molding), SACMI has developed over 1,000 cap designs for customers all over the world.

With SACMI, customers can take advantage of a complete product development service, from cap and preform design to finished product, helping them pinpoint the solutions that best match their needs and production goals.

We know how to modify the neck finish without affecting package performance. Our in-depth understanding of every stage of the process means meticulous attention to cap, preform handling and stretch-blow molding.

Leading the transition towards profitable sustainability.

SACMI seeks to guide the market transition towards profitable sustainability: with these latest GME 30.40 models, there are now more than 30 caps available in the 26/22 mm family, ensuring a reliable response to every production need.

New GME neck finish, the widest range on the market.

SACMI's extensive expertise and experience in integrated cap-neck design has resulted in the widest range of new GME neck finish solutions on the market.